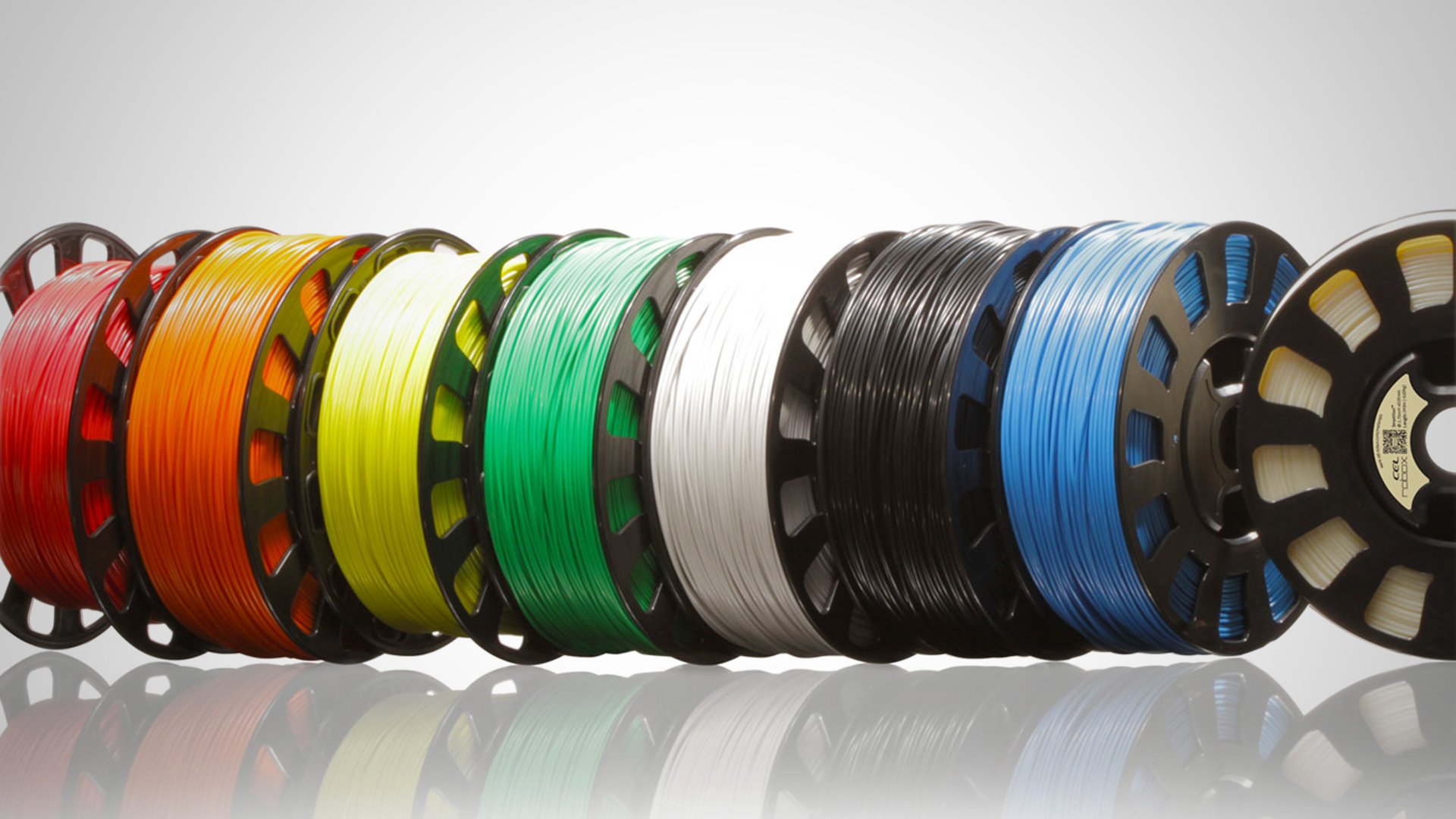

3D Printing Types Of Filament - Choosing the right 3D printer filament is the key to creating successful prints. With so many options available in the market, it can be hard to know where to start. In this guide, we will walk you through 16 common types of 3D printer filaments, their uses, and comparisons to help you make an informed decision.

1. PLA Filament

What is PLA Filament?

PLA (Polylactic Acid) is a thermoplastic filament that is derived from renewable sources such as cornstarch, sugarcane, or tapioca. It is a popular choice among 3D printing enthusiasts because of its low toxicity and biodegradability.

How to Use PLA Filament

PLA filament has a low melting point (around 180°C - 220°C), making it easy to use with a wide range of 3D printers. It also has a low warping tendency, allowing you to print without a heated bed or enclosure. However, PLA can be brittle and prone to breaking, so it may not be suitable for functional parts that require strength.

PLA Filament Pros and Cons

Pros: Environmentally friendly, low toxicity, easy to print, vibrant colors

Cons: Prone to breaking, not suitable for high-temperature applications

2. ABS Filament

What is ABS Filament?

ABS (Acrylonitrile Butadiene Styrene) is a thermoplastic filament that is commonly used in industrial applications. It is known for its toughness, durability, and resistance to high temperatures.

How to Use ABS Filament

ABS filament has a higher melting point (around 220°C - 250°C) than PLA, making it suitable for parts that require strength and durability. However, ABS is more prone to warping and requires a heated bed and enclosure to prevent cracking or curling during printing.

ABS Filament Pros and Cons

Pros: Strong, durable, good for high-temperature applications, available in a wide range of colors

Cons: Prone to warping, requires a heated bed and enclosure, emits fumes during printing

3. PETG Filament

What is PETG Filament?

PETG (Polyethylene Terephthalate Glycol) is a thermoplastic filament that is a combination of both PET and glycol. It is known for its toughness, durability, and resistance to impact.

How to Use PETG Filament

PETG filament has a similar melting point to ABS (around 220°C - 250°C) but has less warping tendency. It can also be printed without an enclosure or heated bed. PETG is a great choice for functional parts that require durability and flexibility.

PETG Filament Pros and Cons

Pros: Tough, durable, impact-resistant, flexible, easy to print

Cons: Limited color options

4. Nylon Filament

What is Nylon Filament?

Nylon is a thermoplastic filament that is known for its strength and durability. It is commonly used in industrial applications such as automotive parts and sports equipment.

How to Use Nylon Filament

Nylon filament has a high melting point (around 240°C - 270°C) and requires a heated bed and enclosure to prevent warping. It also requires additional drying before use to prevent moisture from affecting the quality of the print. Nylon is a great choice for parts that require strength and durability.

Nylon Filament Pros and Cons

Pros: Strong, durable, good for high-stress applications, chemical and heat resistance

Cons: Requires a heated bed and enclosure, difficult to print, hygroscopic (absorbs moisture)

5. TPU Filament

What is TPU Filament?

TPU (Thermoplastic Polyurethane) is a flexible and durable filament that is commonly used in applications that require elasticity and impact resistance. It is also known for its low friction and resistance to oils and chemicals.

How to Use TPU Filament

TPU filament has a low melting point (around 200°C - 230°C) and can be easily printed on most 3D printers. It does not require a heated bed or enclosure and is a great choice for parts that require flexibility and shock absorption.

TPU Filament Pros and Cons

Pros: Flexible, durable, low friction, good impact resistance, chemical and oil resistant

Cons: Limited color options, may require print head modification, can be difficult to print

6. PVA Filament

What is PVA Filament?

PVA (Polyvinyl Alcohol) is a water-soluble filament that is commonly used as a support material for 3D printing. It is known for its ease of use and biodegradability.

How to Use PVA Filament

PVA filament has a low melting point (around 180°C - 230°C) and can be easily printed on most 3D printers. It requires a heated bed and enclosure to prevent warping. PVA is a great choice for support structures that require easy removal and minimal damage to the print.

PVA Filament Pros and Cons

Pros: Water-soluble, easy to use, biodegradable, minimal damage to the print

Cons: Limited applications, requires a heated bed and enclosure, can be expensive

7. HIPS Filament

What is HIPS Filament?

HIPS (High Impact Polystyrene) is a thermoplastic filament that is commonly used as a support material for 3D printing. It is known for its low cost and ease of use.

How to Use HIPS Filament

HIPS filament has a low melting point (around 200°C - 220°C) and can be easily printed on most 3D printers. It requires a heated bed and enclosure to prevent warping. HIPS is a great choice for support structures that require easy removal and minimal damage to the print.

HIPS Filament Pros and Cons

Pros: Low cost, easy to print, minimal damage to the print

Cons: Limited applications, emits fumes during printing, requires a heated bed and enclosure

8. PET Filament

What is PET Filament?

PET (Polyethylene Terephthalate) is a thermoplastic filament that is commonly used in food packaging, water bottles, and other products. It is known for its strength and transparency.

How to Use PET Filament

PET filament has a high melting point (around 230°C - 260°C) and requires a heated bed and enclosure to prevent warping. It is a great choice for parts that require transparency and strength.

PET Filament Pros and Cons

Pros: Strong, transparent, heat resistant, chemical resistant

Cons: Requires a heated bed and enclosure, limited color options

9. Carbon Fiber Filament

What is Carbon Fiber Filament?

Carbon fiber filament is a composite material that is made of a blend of carbon fiber and a thermoplastic binder. It is known for its strength, rigidity, and high-temperature resistance.

How to Use Carbon Fiber Filament

Carbon fiber filament has a high melting point (around 230°C - 280°C) and requires a heated bed and enclosure to prevent warping. It is a great choice for parts that require strength and rigidity, such as drone or RC car components.

Carbon Fiber Filament Pros and Cons

Pros: Strong, rigid, high-temperature resistant, low warping, available in a range of colors

Cons: Difficult to print, expensive, abrasive (can wear down printer nozzle)

10. Wood Filament

What is Wood Filament?

Wood filament is a composite material that is made of a blend of recycled wood particles and a thermoplastic binder. It is known for its natural look and earthy feel.

How to Use Wood Filament

Wood filament has a low melting point (around 180°C - 200°C) and can be easily printed on most 3D printers. It requires a heated bed and enclosure to prevent warping. Wood filament is a great choice for parts that require a natural look and feel, such as figurines or home décor.

Wood Filament Pros and Cons

Pros: Natural look and feel, low price, available in a range of colors, easy to print

Cons: Can clog printer nozzle, requires periodic nozzle cleaning, limited durability

11. Metal Filament

What is Metal Filament?

Metal filament is a composite material that is made of a blend of metal particles and a thermoplastic binder. It is known for its metallic look and feel.

How to Use Metal Filament

Metal filament has a high melting point (around 200°C - 220°C) and requires a heated bed and enclosure to prevent warping. It is a great choice for parts that require a metallic look and feel, such as jewelry or sculptures.

Metal Filament Pros and Cons

Pros: Metallic look and feel, available in a range of metals, easy to print

Cons: Expensive, abrasive (can wear down printer nozzle), limited durability

12. Silk Filament

What is Silk Filament?

Silk filament is a composite material that is made of a blend of polymer and various additives. It is known for its shiny and luxurious finish.

How to Use Silk Filament

Silk filament has a low melting point (around 190°C - 220°C) and can be easily printed on most 3D printers. It requires a heated bed and enclosure to prevent warping. Silk filament is a great choice for decorative parts that require a shiny finish.

Silk Filament Pros and Cons

Pros: Shiny and luxurious finish, available in a range of colors, easy to print

Cons: Limited applications, can be difficult to remove from the print bed, requires a heated bed and enclosure

13. Conductive Filament

What is Conductive Filament?

Conductive filament is a special type of filament that is made of a blend of a conductive material and a thermoplastic binder. It is known for its ability to conduct electricity.

How to Use Conductive Filament

Conductive filament has a variety of applications in industries such as aerospace, robotics, and electronics. It can be printed on most 3D printers and requires a heated bed and enclosure to prevent warping.

Conductive Filament Pros and Cons

Pros: Conducts electricity, can be used in a variety of applications, available in a range of conductivities

Cons: Expensive, abrasive (can wear down printer nozzle), limited durability

14. Magnetic Filament

What is Magnetic Filament?

Magnetic filament is a special type of filament that is infused with magnetic particles. It is known for its ability to attract or repel magnetic objects.

How to Use Magnetic Filament

Magnetic filament has a variety of applications in industries such as aerospace, automotive, and robotics. It can be printed on most 3D printers and requires a heated bed and enclosure to prevent warping.

Magnetic Filament Pros and Cons

Pros: Magnetizes, can be used in a variety of applications, available in a range of magnetic strengths

Cons: Expensive, abrasive (can wear down printer nozzle), limited durability

15. Flexible Filament

What is Flexible Filament?

Flexible filament is a special type of filament that is made of a blend of polymers and other additives. It is known for its ability to bend, stretch, and flex without breaking.

How to Use Flexible Filament

Flexible filament has a low melting point (around 200°C - 220°C) and requires a specialized extruder or print head. It also benefits from a heated bed and enclosure to prevent warping. Flexible filament is a great choice for parts that require flexibility and durability, such as phone cases or shoe soles.

Flexible Filament Pros and Cons

Pros: Flexible, durable, low warping tendency, available in a range of colors

Cons: Requires a specialized extruder or print head, can be difficult to print, limited durability

16. Conductive Filament

What is Conductive Filament?

Conductive filament is a special type of filament that is made of a blend of a conductive material and a thermoplastic binder. It is known for its ability to conduct electricity.

How to Use Conductive Filament

Read more articles about 3d Printing Types Of Filament