3D Printing for Construction Industry - The construction industry is constantly evolving and adopting new technologies to meet demands for innovation and efficiency. 3D printing has emerged as a game-changing technology in the construction sector, changing how we design, build and maintain structures. With the adoption of 3D printing technology in the construction industry, it is possible to build prototypes, customise fittings, and even construct entire buildings in record time. This article explores the ways in which 3D printing is changing the construction industry, including its benefits, limitations, and potential for future growth.

How 3D Printing can Revolutionise the Construction Industry

Building Customisable Parts and Prototypes

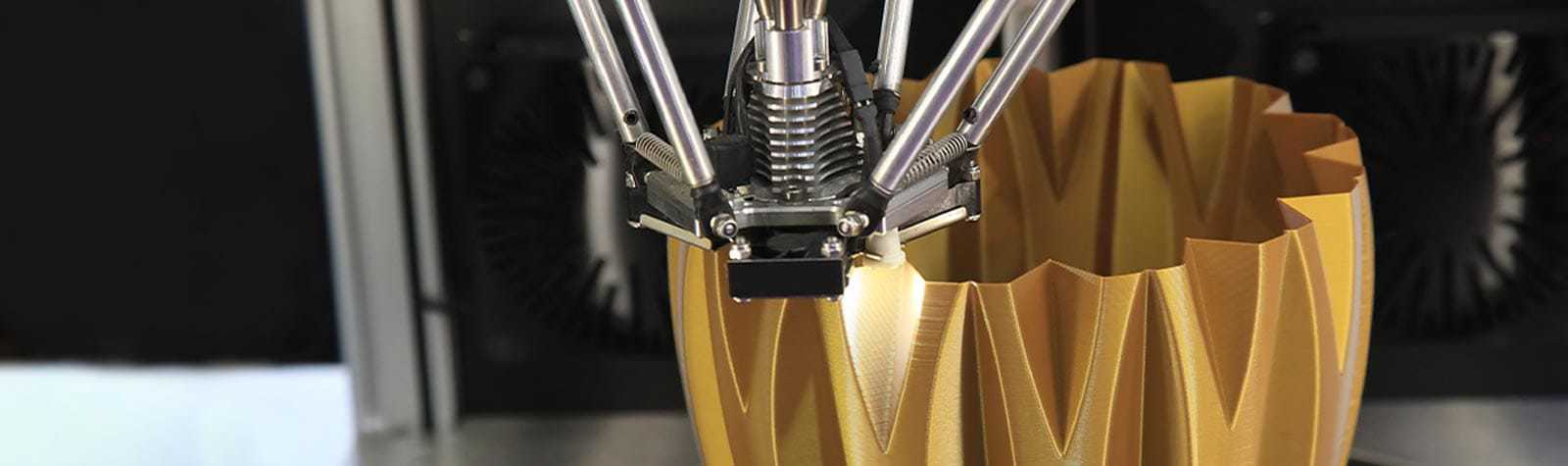

3D printing can produce customised parts on an as-needed basis, instead of waiting for weeks to receive custom parts from a manufacturer. This capability allows engineers to test various designs quickly, rapidly iterating, and perfecting designs with minimal lead time. As a result, the speed of design and development is increased drastically, reducing the overall project timeline.

Building Complex Shapes without the Need for Formwork

3D printing enables the creation of complex shapes that are often difficult or impossible to create with traditional construction methods, without the need for formworks. Formwork is a temporary mould used to shape concrete or other materials while they set, which can be costly and time-consuming to build on-site. With 3D printing, it is possible to print shapes that would have been previously impossible without formwork, saving time and money in the process. This capability opens up opportunities for architects to explore new building designs and to create cost-effective, customised structures.

Constructing Entire Buildings at Speed

The speed of construction is a critical factor in any project, and 3D printing has the potential to speed up the process significantly. Instead of relying on human labour and traditional construction techniques, 3D printing can 'print' an entire building directly on the site, saving time and money. This technology can revolutionise construction in areas such as emergency housing, military barracks, and remote even locations where traditional construction methods are difficult to implement. With the ability to build entire buildings in a matter of days, the technology also has the potential to solve the housing crisis in overpopulated cities quickly and efficiently.

Reducing Construction Waste

3D printing can create objects with precision and accuracy, meaning fewer construction objects end up in landfills. With traditional construction methods, materials like concrete, steel, and timber often go to waste. In contrast, 3D printing technology allows engineers to produce customised parts with exact specifications, and only the necessary amounts of material are used.

Using Greener Materials

3D printing offers increased flexibility in the type of materials that can be used in construction. For example, 3D printing can incorporate recycled materials, which is friendlier to the environment than using virgin materials. The technology is still in its early stages, and there are extensive research and development initiatives exploring different materials, including plastic, clay, and even human-made biodegradable material.

/3D-Printing-56a1bcee5f9b58b7d0c2263e.jpg)

The Limitations of 3D Printing Technology in Construction

Like any technology, 3D printing has its limitations in the construction industry. Currently, it is difficult to 3D print large-scale structures due to the limited printing area, the cost of large-scale printers, and the time required to build structures. In addition, the technology is still in its early stages and has not yet proven to be reliable or consistent in its results. Finally, it remains to be seen how the industry can regulate or enforce quality control on building designs in a 3D printing dominated construction era.

How to Implement 3D Printing in Construction

To get started with 3D printing technology, construction firms will need access to a 3D printer, software to create 3D models, and materials for printing. Firms can purchase their printer or rent it from a 3D printing service provider. Many firms might need to retrain employees or even hire new staff who have skills in 3D modelling and design. There is also a need for collaboration between companies, such as the printer manufacturers and construction companies, to create seamless processes for 3D printing in the construction industry. For example, the use of Building Information Modeling (BIM) software can help to integrate 3D printing designs with the construction process effectively.

The Future of 3D Printing in Construction

The potential for 3D printing in the construction industry is enormous. As the technology evolves, it will become increasingly viable to use it to construct larger and more complex structures. The reliability and consistency of the technology will improve, meaning that it will become more widespread and cost-effective. In the future, we could see a dramatic reduction in the amount of waste in the construction industry, with customised products being produced with a high degree of precision and accuracy, and with materials that are greener and more environmentally friendly.

In conclusion, 3D printing technology presents a tremendous opportunity for the construction industry. 3D printing can solve some of the significant issues in the sector, including the waste of material, time, and cost. The benefits of using 3D printing technology span across all areas of the construction industry, from designing building facades to constructing entire buildings. Although the technology is facing many regulatory and technical hurdles, it is increasingly becoming an essential tool in the construction industry, and one that is sure to transform how we build infrastructure in the years ahead.

Read more articles about 3d Printing For Construction Industry