3D Printing Building Machine Cost - The use of 3D printing technology in construction is becoming increasingly popular. With the development of new materials and techniques, architects and engineers are able to create stunning structures that were once impossible. However, as with any new technology, there are some costs involved. Here are some tips, ideas and how-tos for those interested in 3D printing for construction.

COBOD BOD2 Review - Concrete Construction 3D Printer

The COBOD BOD2 is a state-of-the-art 3D printer specifically designed for construction purposes. It is capable of printing concrete structures up to 10 meters wide, 20 meters long, and 8 meters high. The printer has an accuracy of 1-2mm, making it ideal for large-scale projects such as homes, offices, and commercial buildings. The COBOD BOD2 uses a patented extrusion technology that allows for precise layering of the concrete material, ensuring a strong and durable structure. If you are looking for a reliable, high-quality 3D printer for your construction needs, the COBOD BOD2 is definitely worth considering.

Europe’s First 3D Printed Building (The BOD)

The BOD is a stunning example of the potential of 3D printing technology in construction. Located in Copenhagen, Denmark, the 50-square meter office was built in just three weeks using the massive 3D printer. The building was constructed using a mix of cement and polymer fibers to ensure structural strength and durability. The process of 3D printing the building allowed for the creation of intricate and unique shapes that would have been difficult to achieve using traditional construction methods. The BOD is not only a feat of engineering but also a work of art.

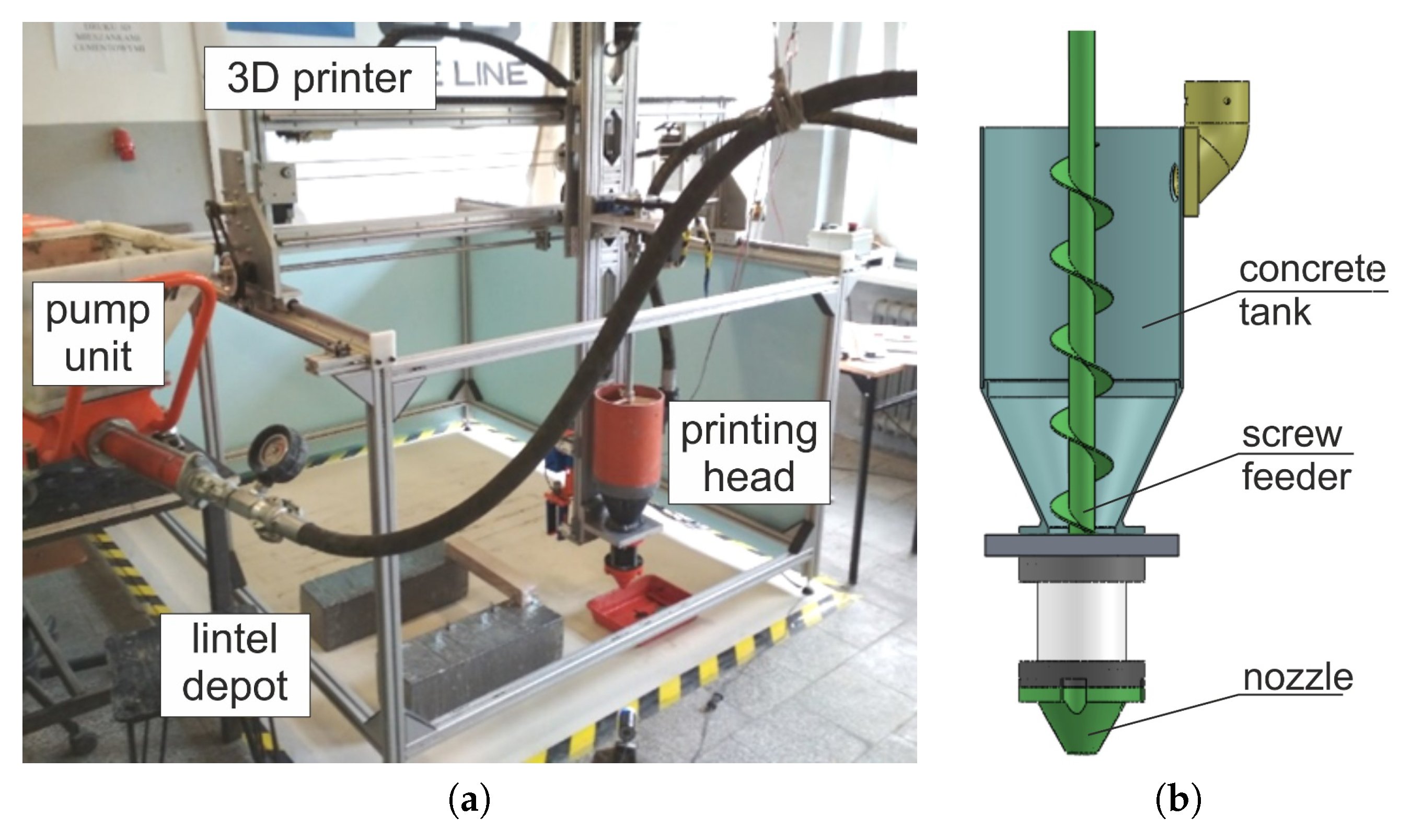

Polish Researchers Explore Automation for 3D Printed Building

Researchers in Poland are exploring ways to automate the 3D printing process for construction. They have developed a system that uses a combination of robotics and 3D printing technology to create walls and other components of buildings. The system is capable of printing both concrete and wooden structures, allowing for a diverse range of construction projects. The use of automation has the potential to significantly reduce costs and increase efficiency in the construction industry. The technology is still in the research phase but shows great promise for the future of 3D printing in construction.

How Much Does 3D Printing Cost?

The cost of 3D printing for construction can vary depending on a number of factors. These include the type of 3D printer, the materials used, and the complexity of the design. 3D printers designed specifically for construction can cost anywhere from $30,000 to $200,000. However, there are also smaller, more affordable 3D printers available for those looking to experiment with the technology. The cost of materials can also vary depending on the type of material used. Concrete and cement materials are typically more expensive than plastic materials. When considering the cost of 3D printing, it is important to factor in the cost of materials, maintenance, and any necessary upgrades.

Conclusion

As 3D printing technology continues to evolve, its potential in the construction industry becomes more and more apparent. With the ability to 3D print complex and unique shapes, as well as the potential for automation and cost savings, 3D printing is set to revolutionize the construction industry. While there are costs involved, the benefits of 3D printing make it a worthwhile investment for those looking to innovate and push the boundaries in the world of construction.

View more articles about 3d Printing Building Machine Cost