How Does 3d Printing Work Video - There's no denying that 3D printing has rapidly become one of the most exciting and rapidly developing technologies of recent times. From the capability to create everything from toys and consumer goods to medical implants and aerospace components, the potential applications for 3D printing are almost limitless. But if you're new to the concept of 3D printing, you might be wondering - how does it work exactly? In this article, we'll take a closer look at the process behind 3D printing, the different types of 3D printing technology available today, and the range of applications for which 3D printing is being used.

Understanding the Basics of 3D Printing

At its core, 3D printing is a process that involves creating three-dimensional objects from a digital design by laying down successive layers of material until the object is complete. This is done using a machine called a 3D printer, which interprets the digital design and uses it to guide the printing process.

When discussing 3D printing, it's important to understand that the process involves several different stages, each of which is essential to the final result. Firstly, the object to be printed must first be designed, typically using computer-aided design (CAD) software. This design is then saved in a file format that can be read by the 3D printer, such as STL or OBJ.

Once the digital design has been created, the next stage is to prepare the 3D printer for printing. This involves loading the printer with the chosen material, such as plastic, metal, or ceramic, and ensuring that the printer's settings are correctly calibrated for the type of material and the desired level of detail in the final object.

With the printer calibrated and the material loaded, the printing process can begin. 3D printing involves adding layers of material one at a time, using a variety of techniques depending on the type of printer being used. Once the final layer is complete, the object is finished, and can be removed from the printer and used as desired.

The Different Types of 3D Printing

Just as there are many different ways to create two-dimensional prints, there are also various techniques and technologies available for 3D printing. Here are some of the most common types of 3D printing technology currently in use:

Fused Deposition Modeling (FDM)

Fused Deposition Modeling, or FDM, is one of the most popular and widely used methods of 3D printing. This technique involves feeding a heated plastic filament through a printer nozzle, which melts the material and extrudes it onto a build platform, layer by layer. FDM printing is relatively affordable and easy to use, making it ideal for home and small business use.

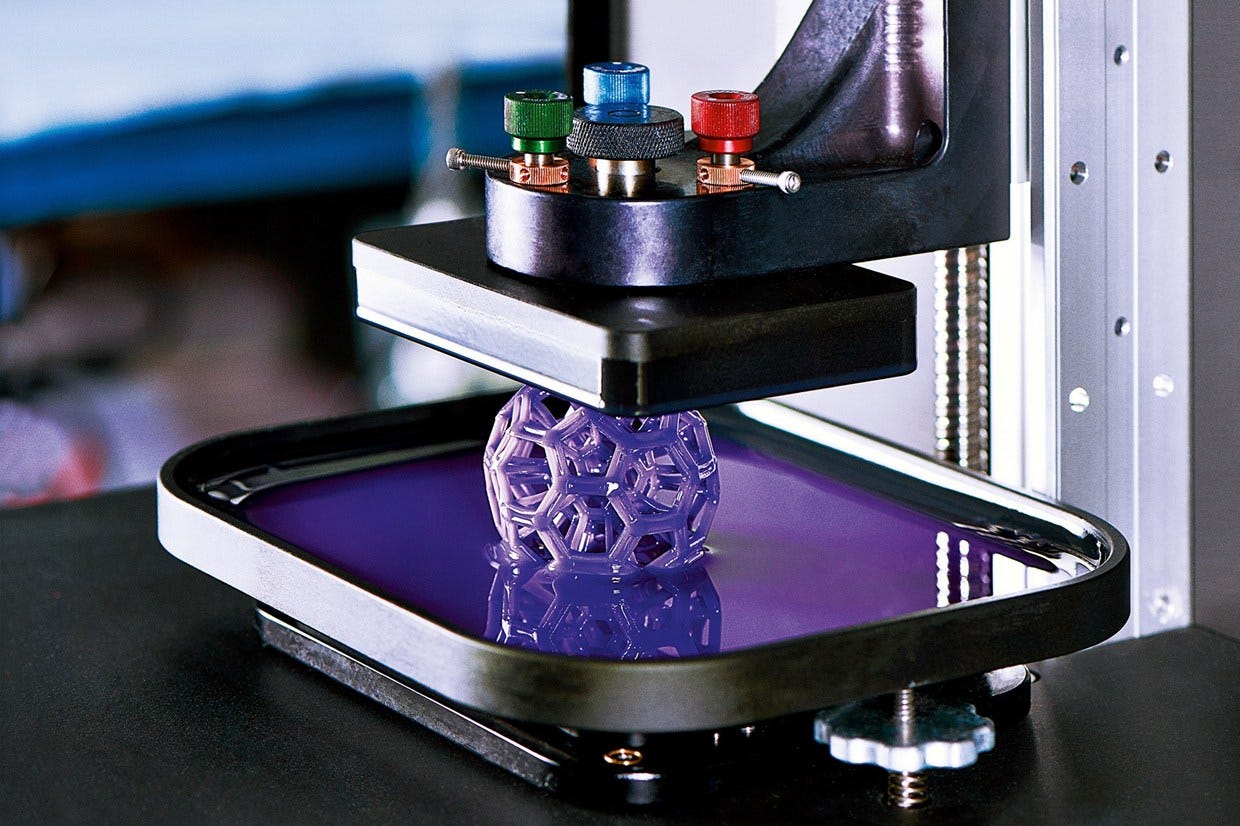

Stereolithography (SLA)

Stereolithography, or SLA, is a 3D printing technique that uses a resin material and a laser to create objects. The laser selectively hardens the resin, which is suspended in a liquid solution, to create the desired shape. SLA printers are known for their ability to produce extremely fine details and smooth surfaces, making them popular for use in jewelry making and other precision industries.

Selective Laser Sintering (SLS)

The Selective Laser Sintering, or SLS, process involves using a laser to selectively fuse together layers of powdered material, such as metal or plastic. As the laser fuses each layer together, the powder bed is lowered, allowing the printer to build up the object one layer at a time. SLS printing is known for its ability to produce durable and high-strength parts, making it popular in industries such as aerospace and automotive.

Direct Energy Deposition (DED)

Direct Energy Deposition, or DED, is a 3D printing technique that uses a laser or electron beam to melt and fuse metal powders, wire or sheets to build objects. The printer nozzle can move in multiple directions, allowing for complex shapes to be produced. DED printing is typically used to produce large-scale objects, or to add features to existing objects such as repairing turbine blades in power plants and aircraft components.

Binder Jetting

Binder Jetting is a 3D printing technique that involves spraying a liquid binder onto a bed of powdered material, such as metal, ceramic, or sand. The binder causes the powder to stick together, creating a solid object. Binder Jetting is extensively used in the production of sand-cast parts in the foundry industry, to create molds for large industrial parts.

How 3D Printing is Being Used Today

Despite only being in use for a few decades, 3D printing has already shown remarkable potential for revolutionizing a wide range of industries. Here are just a few examples of how 3D printing is being used today:

Medical

3D printing is being used in the medical field to create custom implants, prosthetics and scaffolds for tissue engineering. In order to test new drugs and procedures, bio printed tissues like liver, lung and heart are also produced. Additionally, individual surgical models are tailor-made work for a specific patient’s surgical needs making procedures less invasive and more accessible.

Aerospace

The aerospace industry is also a big adopter of 3D printing, with the technology being used to produce complex parts that are difficult or impossible to make using traditional manufacturing methods. These can range from structural components to engine parts, and can be created from a range of materials including metals and composites.

Fashion and Jewellery

3D printing is also being used to produce bespoke jewellery, shoes and clothing. The technique’s ability to produce intricate designs with high quality finishes has allowed new possibilities for ball gowns and designer wear. With the rising interest in customisation among consumers, the fashion industry and luxury goods sector have eagerly latched onto 3DP technology to fuel growth and experimentation in their selections.

Construction

3D printing can also be used for construction, particularly in the creation of building materials such as cement or organic-based materials. The use of 3D printers can speed up production while reducing costs and increasing energy efficiency, such as building homes in disaster-prone areas or in need of emergency housing support.

Tips and Ideas for Getting Started with 3D Printing

If you're interested in exploring the potential of 3D printing, here are some tips and ideas to get you started:

Experiment with Free Online Design Software

There are numerous online design tools available for free that can help you create custom 3D models. Platforms such as Tinkercad, SketchUp, and Blender are popular and can be accessed free of charge.

Invest in a High-Quality 3D Printer

Once you've created your digital designs, you'll need a 3D printer to turn them into physical objects. There are many different models and brands of 3D printer available, ranging from under $200 to several thousand dollars. While cheaper printers are a good option for beginners, investing in a high-quality printer will ensure better printing quality and less headache, efficient for bigger projects or people who work remotely.

Join a 3D Printing Community

If you're feeling lost or confused, don't worry – there are many online communities and forums for 3D printing enthusiasts where you can share ideas, seek advice, and get inspired. Websites such as Thingiverse, MyMiniFactory, and Shapeways are all great resources to find inspiration, connections and learn from other people’s work.

Take Advantage of Online 3D Printing Services

If you don’t want to purchase a 3D printer or you don’t have enough space at your studio or office, then taking advantage of 3D printing services like 3D Hubs, Sculpteo, or Protolabs allows you to upload your 3D model in a variety of formats and material, and have it printed or shipped to you.

3D Printing is Just the Beginning

Considering the numerous benefits and possibilities in both an economic and social perspective, 3D printing is expected to experience significant growth over the next decade. As the technology behind 3D printing continues to develop, who knows what exciting new applications and benefits it will unlock.

So, whether you're a business owner, an entrepreneur, or simply a technology enthusiast, there's no denying that 3D printing is a technology worth exploring. From creating spare parts, intricate designs, life-saving medical implants, and entertainment for films and gaming, the potential applications for 3D printing are almost limitless.Find more articles about How Does 3d Printing Work Video